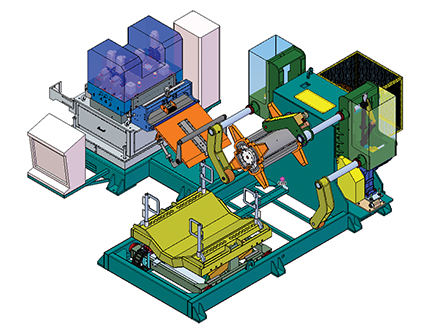

Steel 4.0 - Mercosur Plate Production - Estampo Tec

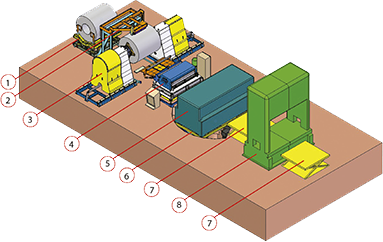

Complete solution developed for our customer for the production of mercosur standart plates

for automobiles and motorcycles.

Equipment used on the line:

🟢 Unwinder;

🟢 Film Aplicator;

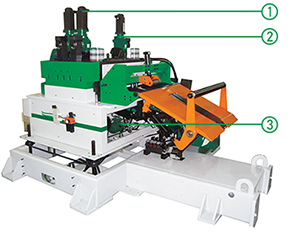

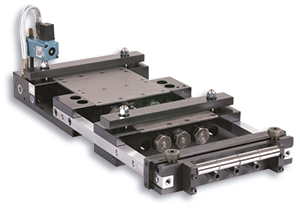

🟢 Feeder:

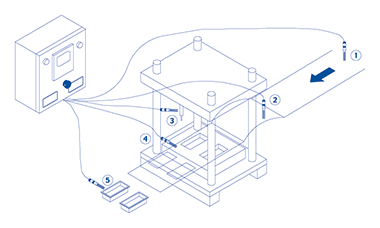

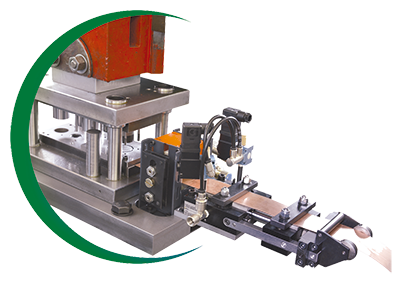

🟢 Stamping Tool;

🟢 Press;

🟢 Conveyor Belt;

Steel 4.0 - A product with quality Estampo Tec